| Mixed wood and bioplastic (PLA) |

What materials to 3D-print ?

Every once a while I'm being asked about it, so here is a post on the many materials that can be 3D-printed at home.It is not complete and will expand with time. It is no buyer's guide either, nor a technical document. Read it as a short generic survey of usable materials.

As for me and many others, I print mostly with PLA filament. Even though I have a set of other materials (wood, rubber, nylon etc), I did not test all the following myself, mostly because each material requires its set of specific time-consuming trials and errors to achieve good quality. Mastering all of them would take me months, if not years!

Once again, the open source / open hardware community rocks, because a lot of enthusiasts explore a lot of subjects... So, for once, I borrowed most of the pictures in this post: check the credits and links for further info. There are probably a few mistakes, so let me know!

One final word of introduction: I willingly omitted materials and techniques incompatible with hobbyists (for now), such as concrete...

PLA: an environmental friendly filament

Polylactic acid is the most common filament used by hobbyists, the other one being ABS.

PLA is a class of environment-friendly plastic which is entirely made out of natural products, hence the organic plastic or bioplastic name. Really, it is a mix of corn starch and sugar cane derivatives that meets food-grade and biodegradability standards and even made its way as surgical suturing.

PLA is a class of environment-friendly plastic which is entirely made out of natural products, hence the organic plastic or bioplastic name. Really, it is a mix of corn starch and sugar cane derivatives that meets food-grade and biodegradability standards and even made its way as surgical suturing.

How strong and biodegradable is PLA in reality ?

|

| The biodegradable PLA stangely resists UV and chlorine in the long term (ref) |

So this plastic is both robust and greener than almost anything I see around me, except for chocolate, clay, and wood may be (see further). A cool, versatile, easy, and useful plastic that needs no oil at all.

Note: some people use home-printed PLA for drinking cups. Still, except for the natural transparent flavor, do not forget that the coloring pigments may not be as harmless as the PLA itself, and they are mostly never documented.

PLA temperatures and strength

Regular PLA usually print very nicely and finely when extruded at around 220°. It releases no fumes and barely smells like pancakes Because it is green as opposed to the other oil-based plastics, you can print inside your house without any danger, not even complaints from your family. |

| Delrin (left) versus hard PLA (ref.) |

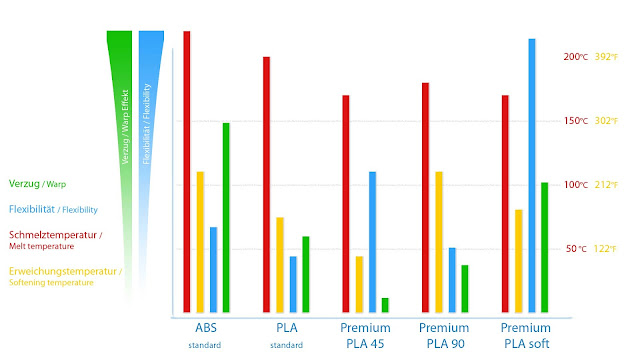

Some PLA flavors are less common but can be very useful for specific requirements, such as lower or higher softening temperatures point (from 45 to 100°) or with a softer or elastic texture (see these printed tank tracks for example -- which is still no rubber though).

|

| This graph comes from orbi-tech, which sells all these variants and much more |

|

| Faberdashery PLA colors |

PLA comes in many colors, including none (clear)

So-called "Natural PLA" is transparent, but you will have tons of colors to chose from, including a fully transparent version, some that embeds shiny particles and some with lower melting temperatures. This makes PLA very well suited to artists and toy makers. Some even made the best of them by switching filament, or even blending different colors at the same time (RichRap rules again). Of course it require a trickier printer setup.PLA comes in different temperatures thresholds and flexibility. The two are not necessarily correlated as shown below.

One nice thing with PLA is that it stays flatter and sticks better than other plastics to the printer bed when it cools down, so your print stays flat and attached to the printer bed. Using a heated bed helps, while it is almost compulsory with ABS for example.

|

| Flashgamer nice post on printing with many colors (excellent picture!) - The related suppliers are listed. |

PLA post-processing

It is easy to re-heat PLA with a hot air gun, a gas torch or a lighter, to repair, bend or weld parts together. Parts can be glued also, but no definitive reference was found. I tend to use super glue, and more flexible glues when appropriate.Finishing a PLA object is definitely more difficult than with ABS plastic for example, where acetone almost does it all ;) Speaking of petroleum derivatives, almost none will impact the organic PLA.

Most of these options are tricky and time consuming though, so I never paint my objects unless for artistic goals ;)

Check Daniel Schneider's wiki post about how to finish printed objects (where the post itself is unfinished, ha!). And also Bertho, with different chemicals (here and there).

PLA really is the preferred choice for many, because of its numerous and interesting properties, among which are its solidity, colors and organic nature.

The ubiquitous ABS plastic

Just have a look around you and you will almost necessary find ABS: from your computer mouse to the waste pipes of your house, Lego bricks and even acid containers.ABS is definitely the other material of choice when it comes to 3D printing. What makes it so common in the industry is that it can also be molded in addition to being extruded. It is cheaper than PLA and it also can be recycled, but contrary to PLA, it is made out of oil (the production of 1 Kg of ABS requires about 2 Kg of oil, see the wikipedia). Obviously it also comes in many colors, including transparent as PLA (but can be made even with some acetone finish, see below).

When cold, ABS is a bit more flexible than regular PLA, and this may be better for some usage as it will stretch before it breaks (thin PLA is somehow elastic but it breaks easily, while thick PLA objects are very sturdy and rigid). ABS filaments seems more homogeneous than the numerous PLA variants (elasticity, transparency, low/hi temperatures). Finally, ABS fails to sunlight: UV radiation makes it brittle in the short/mid term, so it should be used very carefully for outside.

More pros and cons of ABS vs. PLA can be found on this page at protoparadigm (also a buyers's guide), and on Pixilagency.

Printing is done at a somehow higher temperature than PLA (~245°), at which it flows nicely due to a lower viscosity (easier than PLA that solidify quickly and may be trickier in the nose). Make sure neither you nor your pets breathe the toxic fumes that it provokes (though it may not be as harmful as I fear).

Now, ABS curls a lot when it cools down, which pops the part off the bed before the end of the print. A heated bed is then considered a must by many to keep the first layer warm while printing.

Finished ABS objects can be glued or soften with petroleum solvents such as acetone, that also produces a polished look. Contrary to the more recent PLA plastic, there are a lot of options to post-process or paint ABS objects.

For reference you may also check here for a long and technical comparison of oil-based plastics.

PVA as a water-soluble plastic

This is an uncommon but very interesting filament that dissovles in water!It is mainly used as a temporary support structure in dual head printers, to solve overhang issues. One head prints the PVA structure, and the other head prints standard plastic on top of it. Once the object is done, it is drown in water and the PVA magically goes away, freeing the expected mechanical components or overhangs without a need for annoying manual post processing.

PVA thus makes possible some otherwise impossible prints. But it has major drawbacks... Not only is it both expensive, but it also loves so much water that it soon deteriorates due to the ambient air moisture if not properly sealed or dried before use.

Other thermoplastics: nylon, polycarbonate...

Nylon from cheaper trimming lines

Nylon is another oil-based plastic, that has the very advantage to come in the shape of weed whacker or trimming lines (half the price of PLA or ABS filament)! It prints at higher temperature (from 245° to hard-to reach 300°), and also provokes toxic fumes.You'll obviously have less choice regarding color but Nylon has its own set of interesting properties, even compared to ABS, such as a much higher flexibility well suited to gears or phone cases.

Some people recommend drying the filament before use, and keep it in a sealed bag afterwards because it also loves water. Indeed, printing with a non-dry filament results in water evaporating, and the steam creates bubbles in the nozzle that can ruin the print.

Ethylene and polycarbonate (as a crystal clear solid material)

Many other oil-based thermoplastics are available to print with, such as the Polyethylene family (high or low density, for bottle caps, food storage containers such as milk jugs, chemical resistant piping, plastic wraps, or PET for synthetic fibers and clear plastic bottles).In fact, a home 3D printer could print any thermoplastic, that melts and can be shaped into a filament.

The major limitation is reached when "very" high extrusion temperatures are required, because of the limits of most home-grade hot ends (aka extruders). Getting above 300° is generally considered a serious fire and toxic hazard, because of the released gases both from the plastics and from other components of the printer heated end itself (read about how teflon fumes can kills birds for example).

One other plastic worth mentioning is the strong and worthwhile polycarbonate (aka PC or Lexan): don't you have a CD or DVD around? This material is usually seen as crystal clear impact resistant glass, but too low extrusion temperatures seem to degrade a bit these outstanding properties, as described by Richrap (again!). Check also another review at Protoparadigm, which also sells it.

Interesting/promising/experimental materials

Wood filament

|

| Shaded wood owl from this article |

It is reliable as far as I checked (see my dedicated review for the LAYWOO brand, which is the only one available for now -- and is said to have required one year of research). Some people complain that their printer nozzles too often get clobbered by burnt wood though.

By varying the temperature, you also achieve different shades of brown, which gives a very artistic finish as shown here.

Wire (conductive, really!)

A few smart students worked on embedding wire in their objects (OK, not printing really). Their spoolhead is worth a look, or for more details check the full PDF report.

I expect reliable conductive and printable materials to be available in a near future (people mix wood particles with polymers, so why not iron or tin powder). Printing electric tracks is a promising (...or promised?!) grail of 3D printing, because it would be the ground for another paradigm shift up into electronics at home -- it is easy: just add a robot to place and solder electronics components ;)

Plastic pellets and making your own filament

Printing plastic pellets is a grail for 3D printing at home, because they are much cheaper than pre-made filament pools. However, nobody found a reliable and homemade way to print pellets directly with a heated auger screw for example (see also next chapter about extruding paste).Instead, one still need a way to reshape the pellets as filament first, and early functional extruders such as the filabot or lyman slowly open the (hobbyist) path. Now, I would definitely love to write more on the matter (ie. to own one of them!). Still a risky investment for now with its own sets of problems probably. But it opens the door to mixing different and unexpected materials, and it is the only way to recycle the pile of broken parts we all keep for this.

Printing pastes: sugar, chocolate, silicone, wax, clay...

Many people explore these materials, and are now going far beyond writing names on cakes. Well, nobody probably ever tried to do so with silicone of course ;)

Make sure to go and check other RichRap worthwhile explorations!

Extruding clay (ceramics), icing sugar, chocolate or any other kind of solidifying paste requires a serious modification of the printer head, where the hot end must be swapped with a syringe, a peristaltic pump or an auger screw for example. Note that clay is abrasive and may damage any pump or screw in the long term, and that chocolate need to be kept warmed when stored in a large syringe.

Another interesting material to print is wax, not just to make candles but also to print molds as we will see in the following chapter.

|

| Paste/pellet extruder : an outstanding auger screw design by Olaf Diegel. The revolving drill bit drains molten material downwards through the nozzle. |

Another interesting material to print is wax, not just to make candles but also to print molds as we will see in the following chapter.

A lot of work is still underway to solve paste extrusion issues, and it looks like every material has its own set of properties and problems, which usually makes it hard and messy to use for now.

Printing a mold and/or lost wax casting

There are two main techniques for molding that are useful at home, among many in the industry.

Injected molding (low-temperature)

The most direct approach is to design and print the two "negative" parts of a recipient, assemble them, fill the inner gap with a paste such as silicone and let it cure. The molded object is revealed by disassembling the parts (see this excellent tutorial for a flexible bottle, or this easier process for chocolate bars).More than one object can be printed this way. But only a few material, including wax, silicone, or chocolate can be used, because the printed plastic mold itself will not tolerate high temperatures.

Now, "injection" usually means that pressure or vacuum must be used to force the paste in the mold, because of its viscosity and in order to degas any trapped bubble. This is probably the most tricky part of the process.

| William Kempton's brilliant silicone bottle, made out of a two-piece printed mold |

Lost wax casting (metals)

Lost-wax casting is the preferred technique to cast metallic objects.The idea is to print the final "positive" object (aka "investment"), then surround it with a fire-proof mold such as clay (or silicone). Once the outside mold is dry or cured, the embedded printed object is removed by heating it and letting it drip out of the mold, or with use of a vacuum system.

The freed space is then replaced by pouring a molten material into it and/or sucked from the bottom. Actually, this chapter heading should be written "lost plastic casting", because any of our plastics melts out of the mold when heated just like wax.

Some scanned their own brain to make edible chocolate versions of it (the whole process is made very clear). Now, this technique becomes most useful to produce metallic objects, that are otherwise obviously impossible to print or extrude as filaments. Even when selected laser sintering printers become available to hobbyists, fusing iron powders requires a very powerful and extremely dangerous laser (for now, better leave this to experts!).

Here again, the initial "positive" object can also be CAD-tweaked and printed again without less work than hand made.

|

| From printed plastic to cast aluminum, see the ultimaker blog post |

Single or reusable molds?

Whatever the molding technique, the mold must have events to let the initial object flow out (lost wax), and the final molten material poured in (which happens usually under pressure). Sometimes, holes must also be added to "dead ends" of the object, so that poured material leaves no unfilled corners.Finally, the outer mold can be made as two pieces (as pictured in William's bottle above) or as a disposable single embedding part (that will have to be destroyed to reveal the object: you will not be able to re-produce more molded objects in this case).

What else ?

I will add more material and refine this post with time.What I really would start playing with is a filament maker/extruder, because it provides a lot of liberty to mix unexpected compounds. Paste extruders are something else, but a bit off my needs for now. Still I would gladly print candles for the next weeks :)

Addendum: where to buy ?

There are very important variations in the plastic quality and dimensions which may ruin your day: you should definitely double check your selected supplier in the forums before you buy. To start with something, you may peek in the amazing list of suppliers at Reprap as it includes location, price and a short review (all of which may be obsolete!).

Now, there are obviously a few mass-producers for a lot more resellers .. I once found some top-quality filament from an unknown seller on eBay The guy happened to be quite close to the Chinese manufacturer that produced the filament for a well know German reseller their brand name was already printed on the spools I received...

Now, for sure, Chinese suppliers may be less reliable or trustworthy, but at least I know the quality of the plastic of this brand (ie. very good). Whether short-cutting the system is good or bad is another topic I guess, but my idea is not to trust people that dismiss Chinese material as such, while some of "our" best brands just get it from them in the first place.